Team Members: Will Johnston (PI), Janith Godakawela, L. Paige Nobles, Gabrielle Mathews, Amulya Lomte

Awards:

- NASA: University Student Research Challenge (USRC)

- Student team awarded $80,000 for fabrication, testing, and data analysis of AeroFeathers while embarking in a public crowdfunding campaign.

- SAE: Create the Future Design Contest 2023

- Honorable Mention – Aerospace & Defense Category

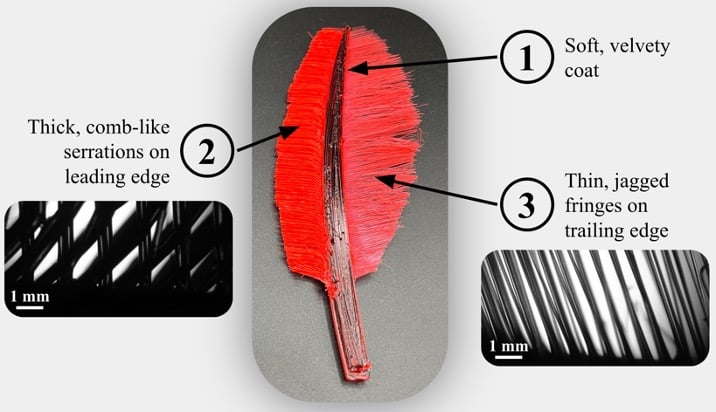

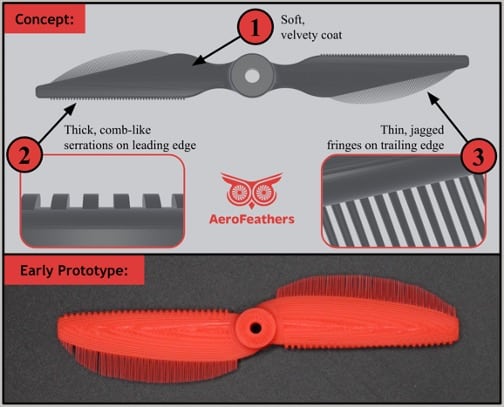

Owls are famous for their noiseless flight, a trait attributed to their specialized feather design. Each feather possesses three critical components: a velvety surface, comb-like leading edge hooks, and fringed trailing edges. Some modern airfoil designs incorporate edge serrations, yet current manufacturing techniques fail to emulate all feather elements, particularly the fine fibers. Our recently published research showcases two innovative methods for 3D printing these thin fibers, enabling the inclusion of fibrous features akin to those of owl feathers to any solid structure. This project will utilize these techniques to create drone propeller blades that mimic the essential characteristics of owl feathers, promising quieter flight than contemporary drones.

The incessant humming of drones can cause considerable nuisance and stress, contributing to noise pollution, particularly in urban settings. This, in turn, can have potential health implications for inhabitants, affecting sleep and concentration. Additionally, quieter drones are less likely to disturb wildlife, preserving natural habitats. Also, noise reduction can enhance user experience, boost public acceptance of drones, and facilitate their use in a wider array of applications. Hence, efforts to reduce drone noise are of paramount importance for a sustainable and harmonious co-existence. Importantly, the project’s technologies can extend beyond aerospace, potentially curbing noise from wind turbines, vacuum cleaners, and hand dryers.

We are developing propeller blades and fixed-wing designs that emulate all the characteristics of an owl feather, delivering substantial noise reduction compared to current designs. Our project objectives include: (1) Refining 3D printing methods to consistently create blades and wings with features like the velvety texture, comb-like serrations (with controlled flexibility), and flexible fibrous fringes found in owl feathers; and (2) investigating how each feather component contributes to reducing the noise generated by the blade.

Our goal is to advance current technology by successfully replicating all owl feather components—such as the velvety tufts and fibrous fringes—that aid in the owl’s silent flight.

Publications: Johnston, W., Godakawela, J., Nobles, L. P., Lomte, A., Carrillo-Munoz, M., & Sharma, B. (2023). AeroFeathers: Feathered airfoils inspired by the quiet flight of owls. The Journal of the Acoustical Society of America, 154(4_supplement), A103-A104.